IN GENERAL

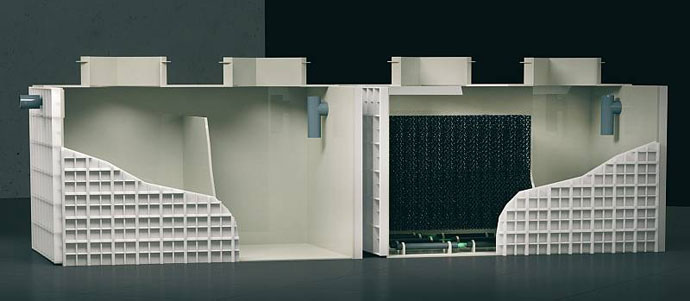

BP FBR is a biological device for the purification of waste water with a submerged biomass carrier and it is used for the purification of sanitary sewerage and industrial waste waters.

It consists of three parts:

• a container for receiving waste water,

• a bioreactor with a biomass carrier

• a secondary settler tank

Leave a Comment